Why Water Based Defoamers Are Ideal for Food Processing and Packaging

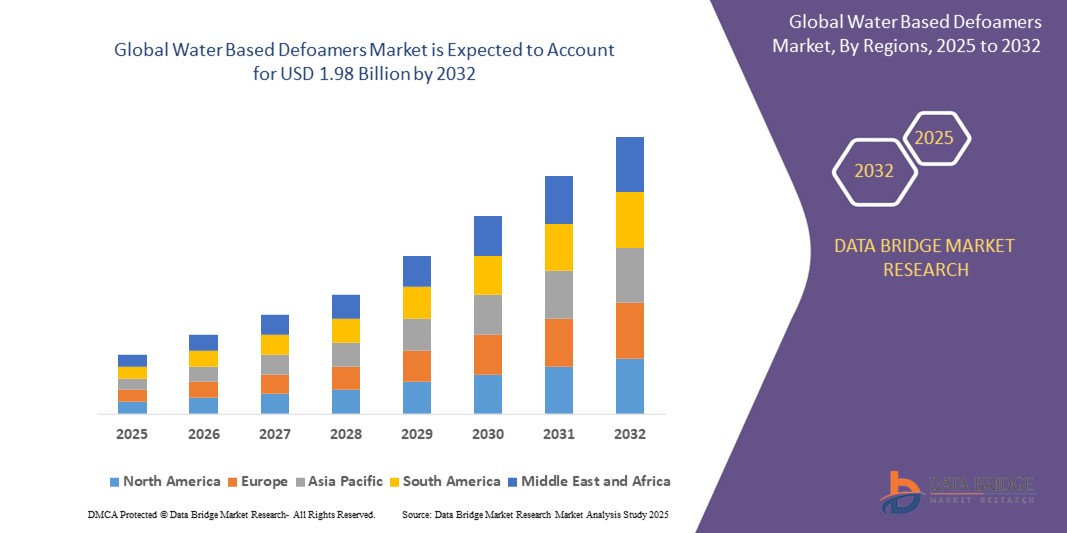

The Water Based Defoamers market was valued at USD 1.29 Billion in 2024 and is expected to reach USD 1.98...

Introduction

In the dynamic world of food processing and packaging, efficiency, hygiene, and safety are top priorities. Among the many materials and additives used in the industry, defoamers play a critical role in maintaining productivity and product quality. Foam can interfere with equipment, reduce filling accuracy, delay processing, and pose contamination risks. This is where water-based defoamers come into the picture as an ideal solution. Designed for compatibility with aqueous systems, water-based defoamers offer a host of benefits, particularly in environments where health standards and safety regulations are paramount.

Definition

Water based defoamers are chemical additives formulated to reduce or eliminate unwanted foam in water-containing systems. They work by disrupting the foam’s surface tension, causing bubbles to collapse and preventing foam formation during industrial processes like wastewater treatment, paper manufacturing, and paints.

Understanding Defoamers and Their Role

Foam is a common byproduct of many industrial processes involving agitation, aeration, and surfactants. In food processing, foam can form during the mixing, fermenting, cooking, and cleaning stages. It may be caused by proteins, sugars, fats, and added surfactants interacting with mechanical operations.

Defoamers or anti-foaming agents, are chemical additives used to prevent and control foam generation. They function by destabilizing foam bubbles, allowing them to collapse and dissipate quickly. Defoamers are broadly categorized into types based on their formulation, including silicone-based, oil-based, and water-based defoamers.

What Are Water-Based Defoamers?

Water-based defoamers are formulations where water acts as the primary carrier fluid. These defoamers typically contain:

- Emulsified oils or waxes

- Hydrophobic particles

- Surfactants and other foam-breaking agents

They are designed for systems where water is the dominant medium, making them especially suitable for aqueous food processing operations such as beverage manufacturing, vegetable washing, dairy processing, and cleaning-in-place (CIP) systems.

Why Water-Based Defoamers Are Ideal for Food Processing and Packaging

1. Food Safety and Regulatory Compliance

One of the primary concerns in the food industry is adherence to safety and hygiene regulations. Water-based defoamers are typically formulated to meet food-grade standards, including approval from organizations such as the FDA (Food and Drug Administration) and NSF International.

These defoamers are often:

- Non-toxic

- Biodegradable

- Compliant with 21 CFR regulations for indirect food contact

This ensures that even in the case of incidental contact with food products, water-based defoamers do not pose any risk to consumer health.

2. High Compatibility with Aqueous Systems

Since many food processing operations rely on water as a processing medium, water-based defoamers offer natural compatibility. They disperse easily in aqueous solutions without leaving residues or requiring complex mixing processes. This results in:

- Faster and more efficient foam control

- Better coverage in cleaning systems

- Reduced risk of product contamination

3. Environmental Friendliness

Sustainability is becoming an increasingly important focus in the food industry. Water-based defoamers are generally considered more eco-friendly than oil-based or solvent-based alternatives due to their:

- Low VOC content (Volatile Organic Compounds)

- Biodegradability

- Lower environmental footprint during production and disposal

As part of their dedication to environmentally responsible practices and green production, many food processors select water-based defoamers.

4. Low Residue and Easy Cleanup

Water-based defoamers are designed to be easily rinsed away, making them ideal for operations that require frequent cleaning and strict sanitation protocols. They don’t leave behind greasy residues or films that could interfere with machinery or taint food products.

This is especially important in sectors like dairy, beer brewing, and soft drink production, where residue can affect both taste and shelf life.

5. Cost Efficiency and Operational Advantages

While some may perceive water-based defoamers as less aggressive than silicone or oil-based types, their performance in moderate to high-foam systems is often more than sufficient when applied correctly. Their cost efficiency comes from:

- Lower application rates

- Reduced need for cleaning chemicals

- Decreased downtime due to foam-related slowdowns

In automated systems and high-speed packaging lines, even slight foam delays can impact production. Water-based defoamers maintain a smooth and effective process.

Applications in Food Processing and Packaging

Water-based defoamers can be found in various parts of the food production chain. Key applications include:

- Beverage Manufacturing: Carbonated drinks, juices, and milk can create foam during filling. Water-based defoamers help control foam during bottle or can filling operations to avoid overflows and ensure fill accuracy.

- Vegetable and Fruit Washing: Foam can build up during washing due to organic material and detergents. Defoamers keep conveyer rinse lines and washing tanks from foaming.

- Fermentation Processes: In baking, brewing, and dairy fermentation, foam can hinder microbial activity or overflow tanks. Water-based defoamers maintain clean operation without compromising fermentation.

- Meat and Poultry Processing: During cleaning and sanitization, defoamers prevent foam buildup in tanks and pipes, ensuring thorough sanitation and reducing rinse times.

- Cleaning-In-Place (CIP) Systems: CIP systems rely on strong detergents and high-pressure water, often generating foam. Water-based defoamers break down foam quickly, enhancing cleaning efficiency and water use.

Choosing the Right Water-Based Defoamer

Not all water-based defoamers are created equal. When selecting one for your food processing needs, consider the following:

- Food-Grade Certification: Always verify the product meets FDA or NSF standards for food processing applications.

- Thermal Stability: Ensure it performs effectively under varying temperatures, especially if used in pasteurization or cooking systems.

- Shear Resistance: It should withstand mixing and pumping without losing effectiveness.

- Residue Profile: Look for products that leave minimal or no residue.

- Application Method: Determine whether the defoamer is best used as a batch additive, in-line injection, or spray application.

Future Trends and Innovations of Water-Based Defoamers Market

1. Bio-Based and Sustainable Formulations

Manufacturers are turning to bio-based water defoamers derived from renewable resources as sustainability gains international attention. These environmentally friendly alternatives are gaining traction in food and beverage applications due to their lower carbon footprint and reduced toxicity.

2. Enhanced Food-Grade Compliance

There is a growing focus on producing defoamers that meet stricter food safety regulations across various regions. Future innovations will include formulations with clean-label ingredients, non-GMO components, and improved allergen-free profiles to cater to evolving consumer demands.

3. Smart Dosing and Automation Integration

Emerging technologies are enabling automated dosing systems that monitor foam levels in real-time and adjust defoamer usage accordingly. This ensures consistent performance, reduces waste, and enhances process efficiency in large-scale food manufacturing.

4. Nanotechnology and Performance Boosters

Nanotechnology is being explored to develop high-performance water-based defoamers with better foam control at lower concentrations. These innovations aim to improve spreadability, stability, and foam suppression even under high shear or temperature conditions.

Growth Rate of Water Based Defoamers Market

According to Data Bridge Market Research, the size of the worldwide water based defoamers market was estimated at USD 1.29 billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 5.50% to reach USD 1.98 billion by 2032.

Learn More: https://www.databridgemarketresearch.com/reports/global-water-based-defoamers-market

Conclusion

Water-based defoamers are proving to be an indispensable asset in the food processing and packaging industries. With their excellent compatibility, food-safe properties, and eco-friendly profile, they help manufacturers maintain high-quality standards while optimizing production efficiency. From beverage bottling to CIP systems, these defoamers contribute significantly to safe, clean, and cost-effective food production.