Bioprocessing Reagents: The Backbone of Modern Biomanufacturing

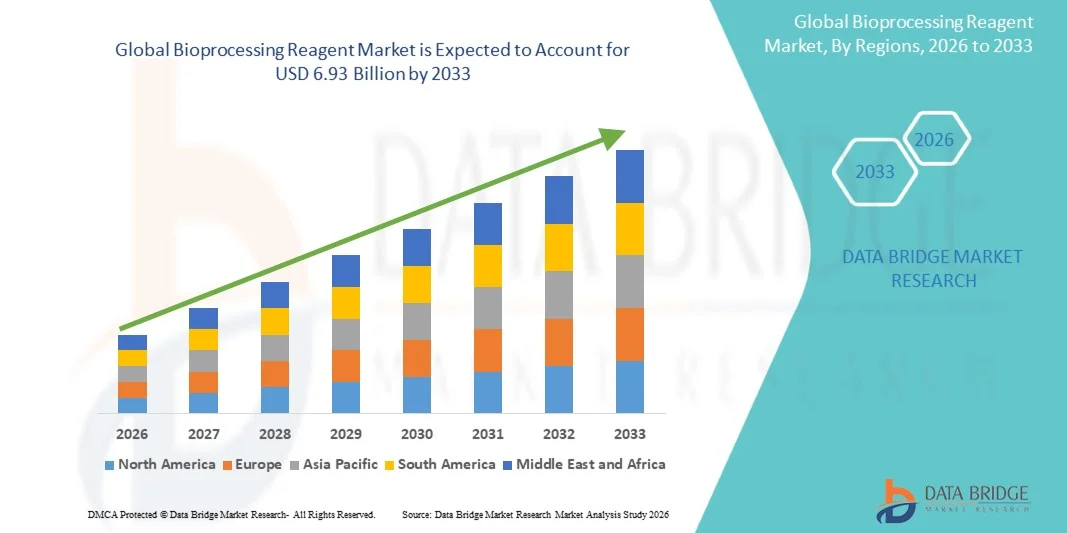

The Global Bioprocessing Reagent Market was valued at USD 3.43 Billion in 2025 and is expected to reach USD 6.93...

Introduction

The biopharmaceutical industry has experienced remarkable growth over the past few decades, driven by advances in biotechnology, cell culture, and downstream processing. At the heart of this progress lies a critical yet often underappreciated component: bioprocessing reagents. These reagents play a fundamental role in every stage of biomanufacturing, from upstream cell cultivation to downstream purification and final formulation.

Definition

A bioprocessing reagent is a chemical, biological, or biochemical substance used to enable, control, or optimize biological manufacturing processes, particularly those involving cells, enzymes, or microorganisms. These reagents support critical steps such as cell culture, fermentation, purification, separation, and analysis in the production of biopharmaceuticals, vaccines, cell and gene therapies, and other biologically derived products. Examples include buffers, media components, growth factors, enzymes, resins, and solvents, all of which are designed to meet strict quality, consistency, and regulatory standards. Bioprocessing reagents play a key role in ensuring product yield, purity, safety, and reproducibility throughout the biomanufacturing workflow.

What Are Bioprocessing Reagents?

Bioprocessing reagents are specialized chemical, biological, or biochemical substances used to support, control, or optimize biological processes in manufacturing. They are essential for maintaining cell viability, enhancing productivity, ensuring product purity, and meeting regulatory requirements.

Unlike general laboratory chemicals, bioprocessing reagents are often produced under strict quality standards, such as GMP (Good Manufacturing Practice), to ensure consistency, safety, and traceability. Their performance directly impacts yield, process robustness, and ultimately the quality of the final biopharmaceutical product.

Key Types of Bioprocessing Reagents

Bioprocessing reagents can be broadly categorized based on their role in the manufacturing workflow.

1. Cell Culture Media and Supplements

Cell culture media are among the most critical bioprocessing reagents. They provide essential nutrients – such as amino acids, vitamins, salts, and energy sources – required for cell growth and protein expression.

Modern biomanufacturing increasingly relies on serum-free and chemically defined media, which reduce variability and improve regulatory compliance. Supplements such as growth factors, cytokines, lipids, and trace elements are often added to fine-tune cell performance and boost productivity.

2. Buffers and Solutions

Buffers are used throughout upstream and downstream processes to maintain optimal pH and ionic strength. Common buffers include phosphate, Tris, acetate, and citrate systems.

In downstream processing, buffers are critical for chromatography steps, viral inactivation, and formulation. Consistent buffer quality is essential for reproducibility and scale-up, making them a cornerstone of reliable bioprocessing.

3. Enzymes

Enzymes are highly specific bioprocessing reagents used for tasks such as cell lysis, nucleic acid digestion, and protein modification. Examples include proteases, nucleases, and glycosidases.

In downstream purification, enzymes like endonucleases help reduce host cell DNA, improving product purity and meeting regulatory limits. High-purity, animal-origin-free enzymes are especially valued in therapeutic manufacturing.

4. Chromatography Resins and Ligands

While often considered consumables rather than reagents, chromatography materials are indispensable to downstream processing. Affinity ligands (such as Protein A), ion-exchange reagents, and hydrophobic interaction materials enable selective separation of target biomolecules.

Advances in ligand stability and binding capacity have significantly improved process efficiency and reduced costs, especially for monoclonal antibody production.

5. Process Aids and Additives

Process aids include antifoaming agents, reducing agents, detergents, and stabilizers. These reagents help control physical and chemical conditions during fermentation, purification, and formulation.

For example, antifoams prevent excessive foam formation in bioreactors, while surfactants can stabilize proteins during filtration and storage.

Applications of Bioprocessing Reagents

Bioprocessing reagents are used across a wide range of applications, including:

- Monoclonal antibody production

- Recombinant protein manufacturing

- Vaccine development

- Cell and gene therapy

- Enzyme and industrial biotechnology

Each application has unique requirements for reagent purity, consistency, and regulatory documentation. As therapies become more complex, reagent performance becomes increasingly critical.

Quality and Regulatory Considerations

In biopharmaceutical manufacturing, reagent quality is non-negotiable. Regulatory agencies such as the FDA and EMA require thorough documentation, including certificates of analysis, traceability of raw materials, and risk assessments related to animal-derived components.

The shift toward animal-origin-free (AOF) and chemically defined reagents reflects the industry’s focus on safety, reproducibility, and regulatory compliance. Suppliers of bioprocessing reagents must demonstrate robust quality systems and long-term supply reliability.

Emerging Trends in Bioprocessing Reagents

The bioprocessing landscape is rapidly evolving, and reagent development is keeping pace. Some key trends include:

Single-Use and Ready-to-Use Formats:

Pre-mixed, sterile, and ready-to-use reagents reduce preparation time, contamination risk, and operational complexity, particularly in single-use bioprocessing facilities.

Custom and Application-Specific Reagents:

Manufacturers increasingly demand tailored reagents optimized for specific cell lines or processes, driving collaboration between reagent suppliers and biopharma companies.

Sustainability and Supply Chain Resilience:

There is growing emphasis on sustainable sourcing, reduced waste, and secure supply chains, especially after global disruptions highlighted vulnerabilities in reagent availability.

Support for Advanced Therapies:

Cell and gene therapies require highly specialized reagents with ultra-high purity and consistency, opening new opportunities for innovation in reagent design.

Growth Rate of Bioprocessing Reagent Market

According to Data Bridge Market Research, the bioprocessing reagent market was estimated to be worth USD 3.43 billion in 2025 and is projected to grow at a compound annual growth rate (CAGR) of 9.2% to reach USD 6.93 billion by 2033.

Read More: https://www.databridgemarketresearch.com/reports/global-bioprocessing-reagent-market

Conclusion

Bioprocessing reagents are the unsung heroes of modern biomanufacturing. From enabling robust cell growth to ensuring high-purity final products, their impact spans the entire production lifecycle. As biologics and advanced therapies continue to shape the future of medicine, the demand for reliable, high-performance bioprocessing reagents will only increase.